Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

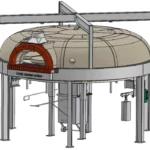

Read moreWood-fired pizza oven 2000R with a rotating floor and rotating trays

Discover Four Grand-Mère’s largest oven with rotating floor and trays for pizzerias and restaurants: the 2000R wood-fired oven.

- 13 trays Ø 32 cm

- 12 trays Ø 36 cm

- 9 trays Ø 46 cm

- 10 trays Ø 40 cm

| Number of rotary tables | 9 to 13 |

| External dimensions D x W x H (m) | 2,37 × 2,33 × 2,09 |

| Weight of oven (kg) | 2650 |

| Door size | 50 |

| Number of Ø 30-31 cm pizzas per batch | 13 |

| Number of Ø 30-31 cm pizzas per hour | 156 |

Need a helping hand? We can help!

+33 (0)3 29 65 20 53The 2000R rotating floor wood-fired oven is specially designed to offer professionals a high-performance wood-fired cooking solution. It is part of the range of rotating wood-fired ovens with rotating trays, and is available with a firebox positioned on the left or right. Its system, designed exclusively by Four Grand-Mère, with its rotating floor and rotating plates, makes it particularly efficient for even cooking of pizzas and tarts flambées, without any handling during cooking.

The 2000R oven offers several tray configurations, depending on the diameter of your pizzas: 13 x 32 cm trays, 12 x 36 cm trays, 9 x 46 cm trays, or 10 x 40 cm trays. Thanks to the rotating floor and rotating trays, the pizzas rotate automatically in front of the fire, ensuring even cooking without the intervention of the pizza maker. At the end of the cycle, the pizzas are perfectly cooked and ready to be removed from the oven.

The 2000R oven features a rotating floor with adjustable speed, giving pizza maker precise control over baking. By eliminating the need for constant monitoring and handling of pizzas, this oven optimizes work (which can even be entrusted to unskilled employee). Thanks to the automatic rotation and stopping of trays in front of the door, loading and unloading pizzas is also greatly simplified.

The 2000R model includes a made-to-measure cladding made of powder-coated steel and/or stainless steel. Manufactured in our workshops, this cladding can cover the entire oven, including the upper part and the lower metal table, or just the upper part, according to your wishes. This customization guarantees a high-quality finish, adapted to your aesthetic requirements.

The 2000 R rotating floor and trays oven is available in a combined wood and gas version, combining the advantages of wood-fired cooking with the convenience of gas heating.

Warranty and after-sales service.

Oven made in France, in our workshops. 5-year parts warranty throughout the European Union, Great Britain, Norway and Switzerland for intensive professional use.

The features of your rotating floor and rotating plates oven 2000R in detail :

- A rotating floor consisting of rotating trays (12 x Ø 36 cm or 9 x Ø 46 cm or 13 x Ø 32 cm or 10 x Ø 40 cm).

- A Chamotte concrete 8 cm thick vault.

- Complete oven insulation (lower layer in vermiculite slab, upper layer in 3 layers of high-temperature mineral fibre, 63 mm thick).

- A metal table.

- A powder-coated steel and/or stainless steel cladding.

- 18 kW geared motor with variable speed drive.A refractory Chamotte concrete fireplace with a grate under the fire place.

- Andiron.

- Grease.

- A cast-iron door Grand-Mère 50 cm.

- A removable 50 cm insulating door.

- 1 flue connector Ø 180 mm with damper.

- One smoke collector Ø 250 mm.

- Technical file with installation and operating instructions

Wood-fired pizza oven 2000R with a rotating floor and rotating trays

Wood-fired pizza oven 2000R with a rotating floor and rotating trays

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

Download documents

- Plan 2000 R Download

options

The “2 doors” option for a wood-fired oven adds a second opening, offering greater flexibility in its use.

The addition of this second door allows you to load the baking room and remove pizzas cooked by either of the 2 doors. You can also install a glass door just for the unique spectacle of the flames, and create a warm atmosphere. Depending on requirements, this second entrance can be positioned at different angles (90°, 135° or 180°), to suit any configuration.

Thanks to this recipe specially designed for wood-fired cooking, treat your guests to a tender, flavourful turkey that's golden brown to perfection.

Thanks to this recipe specially designed for wood-fired cooking, treat your guests to a tender, flavourful turkey that's golden brown to perfection.