Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

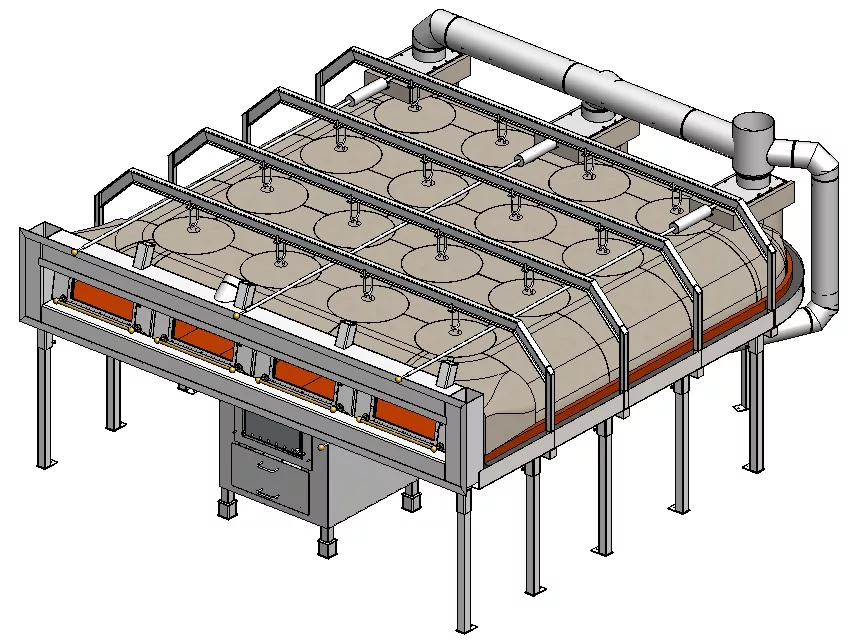

Read moreOven 3333 for bakers with an inferior fire box set below the baking room and a throat with a loading via an inlet belt conveyor.

Discover the oven 3333 with a lower fire box and a throat for the loading via a belt conveyor. Designed for large bakeries, it can bake till 153 baguettes or 98 loaves of 500 g per batch.

| Surface area of sole (m²) | 10,90 |

| External dimensions D x W x H (m) | 3,66 x 3,66 x 2,31 |

| Baguettes per batch | 153 |

| Number of 500 g loaves per batch | 98 |

| Nombre de portes d’enfournement | 4 |

Need a helping hand? We can help!

+33 (0)3 29 65 20 53Designed for very large bakeries that want to bake their breads over a wood-fired oven, this is not only the largest oven in the lower fire box with a conveyor oven range, but also the largest bakery oven manufactured by Four Grand-Mère. With its 4 loading doors, this bakery oven can bake up to 153 baguettes or 98 loaves of 500 g bread per batch!

This oven like the others of this range, has a “throat “ and inferior fire box set below the baking room, communicating with the baking room via the throat system. This throat system can be manually manipulated to direct the flames to different parts of the baking room and fire box, ensuring excellent heat distribution throughout the baking room. Once the desired oven temperature has been reached, the throat is removed and covered by a slot cover.

Square or rectangular in shape, this oven is designed for loading on a belt conveyor, but can also be loaded with a shovel. This floor made of paving bricks 6 cm thick, its refractory concrete chamotte vault 8 cm thick, has remarkable inertia thanks to the quality and thickness of the materials used, and its excellent insulation, which guarantees perfectly controlled bread baking quality, and also offers the possibility of baking several batches without refuelling.

Guarantee and customer service.

Oven made in France, in our workshops. Spare parts guaranteed for 5 years for the chamotte concrete version and 10 years for the brick version throughout the European Union, Great Britain, Norway and Switzerland for intensive professional use.

3333 lower fire box set below the baking room and a throat designed for a loading via an inlet belt conveyor in detail.

- 4 flip up doors, 762 mm passage width, with attractive brass handle and glass inclusion.

- 2 sight glasses lights inside the baking room

- 1 capillary needle thermometer with a 100 mm diameter dial.

- A metal stand for this oven that is easy to fit

- 4 metal frames to hang the vault

- The 8 cm thick refractory concrete chamotte vault (or brick as an option).

- Insulating the vault with 3 coats of high-temperature mineral fibre.

- The floor is made of 33×33 cm refractory bricks, 6 cm thick.

- Insulating of the floor with vermiculite and rock wool panels (8 cm + 2 cm).

- An inferior fire box set below with a Ø 30 cm removable throat with a hooked operating lever and a slot cover.

- 1 flue connector for the exhaust of the fire box.

- 2 flues at the back of the oven and controlled from the front face with 2 brass handles and the outlets connections

- 1 steam device with 2 copper water tanks and two 20 kg steel walls integrated into the vault.

- The assembly grout (clay powder )

- Installation and operating instructions

- 1 removable ash bin

- 1 double brass brush (3,50 m).

- 1 fire pick (2,20 m).

- 1 fire scraper (2,20 m).

Oven 3333 for bakers with an inferior fire box set below the baking room and a throat with a loading via an inlet belt conveyor.

Oven 3333 for bakers with an inferior fire box set below the baking room and a throat with a loading via an inlet belt conveyor.

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

Download documents

- Plan FSPC3333GI Download

options

Four Grand-Mère offers a loading conveyor for its lower fire box with a throat ovens. This belt facilitates bread loading and moves horizontally with three adjustable heights :

- Low Height : table-height for bread arrangement.

- Medium height : Aligned with loading height for easy insertion.

- High height : Approx. 1m80, allowing movement under the mat

Optimize your workspace and improve loading efficiency with this practical option.

The brick vault option replaces the chamotte concrete vault with a refractory brick vault. This choice of traditional bread oven material brings the unique benefits of refractory brick, including better heat retention and distribution, optimum heat radiation, and exceptional longevity.

The brick vault ensures that the bread is baked more evenly and to a higher quality.

Four Grand-Mère offers customized stainless steel cladding for its bakery ovens. This cover improves the aesthetics and hygiene of your oven by offering a design adapted to your specific needs. Made from stainless steel sheet, it is durable, hard-wearing and easy to clean. It also provides a professional finish, adding a modern and elegant look to your oven.