Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

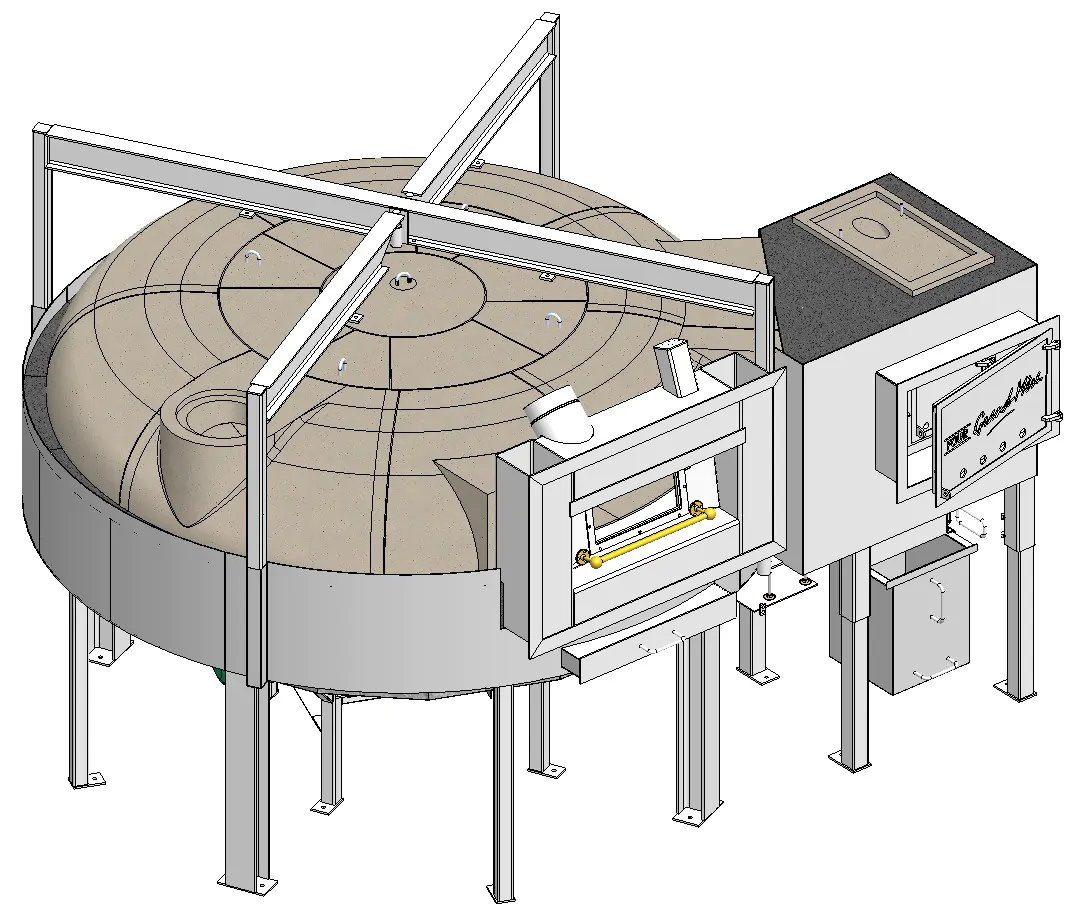

Read moreWood-fired oven with rotating floor for bakers R 2500 FL

Designed for bakeries, this bread oven with rotating floor and side fired rotating bread oven, evenly bakes all kinds of bread and pastries !

| Surface area of sole (m²) | 4,9 |

| External dimensions D x W x H (m) | 2,89 × 3,31 × 2,10 |

| Baguettes per batch | 78 |

| Number of 500 g loaves per batch | 54 |

| Power (kW) | 180 |

Need a helping hand? We can help!

+33 (0)3 29 65 20 53Ideal for the bakeries, the R 2500 FL is the middle-size of the range of Rotating wood fired oven with a side firebox.

Thanks to its rotating floor which passes at constant speed in all areas of the baking room, this oven is capable of uniformly cooking 120 baguettes or 70 loaves

of 500 g per hour.

Very easy to use, it combines all the advantages of the side firebox and the rotating floor. You can start, stop or adjust the speed of the motorised floor with a simple touch of the control panel.

The R 2500 FL oven is available with a refractory “fireclay” chamotte vault and a choice of left or right side fireboxes. This model incorporates two passive steam systems consisting of two water device, each fed by a solenoid valve and controlled individually, ensuring the best steam dosage for a golden crust and well-risen bread.

Thanks to these 2 processes, you can send enough steam into the baking room at the start of baking to obtain a shiny crust and a well-risen loaf.

Thanks to a steam extractor linked to a fan it sends a delicious bread smell into the shop or out into the street, as you prefer.

Guarantee and customer service.

Oven made in France, in our workshops. 5-year parts warranty throughout the European Union, Great Britain, Norway and Switzerland for intensive professional use.

The features of your R 2500 FL rotating oven in detail

- A retractable steel door with brass handle, glass inclusion and cooking chamber lighting.

- 1 removable drawer recessed under the oven door to collect ash and dust from the floor.

- 1 door-mounted steam extractor with flexible hose and fan.

- 1 capillary needle thermometer with a dial diameter of 100 mm.

- The metal support that includes the electric motor for rotating the floor.

- 2 steel frames metal to suspend the vault.

- A refractory vault (chamotte mortar) 8 cm thick.

- Insulation of the vault with 3 layers of high temperature mineral fiber.

- The 8 cm thick refractory floor (Ø 2500 mm) with food contact approval (chamotte mortar) in 2 layers of 4 cm each.

- Mineral fibre insulation for the floor (8 cm).

- A side firebox (maximum wood length 65 cm) with flap throat controlled from the front.

- 1 large removable ashtray on sliding wheels under the firebox

- 1 front-operated firebox outlet and its connection flue

- 2 baking chamber flues controlled from the front of the oven and the main connection flue.

- 1 smoke header with an internal diameter of 250 mm for connecting the flues to the main exhaust flue.

- 1 control panel (floor rotation, steam devices, lighting and steam extractor).

- 2 passive steam system with a water device integrated in a vault piece (20 kg), operated by 2 solenoid valves.

- 1 removable ashtray.

- The assembly grout (clay powder).

- Installation and operating instructions.

Wood-fired oven with rotating floor for bakers R 2500 FL

Wood-fired oven with rotating floor for bakers R 2500 FL

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

Download documents

- Plan FBOULR2500FL Download

options

Adorned with beautiful ears of wheat, this cast-iron door is said to open automatically, meaning it opens and closes with a simple sweep of the shovel. It can also be operated in a more conventional, effortless way, using a handle with a counterweight.