Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

Read moreOur wood fired ovens for pizzerias and restaurants

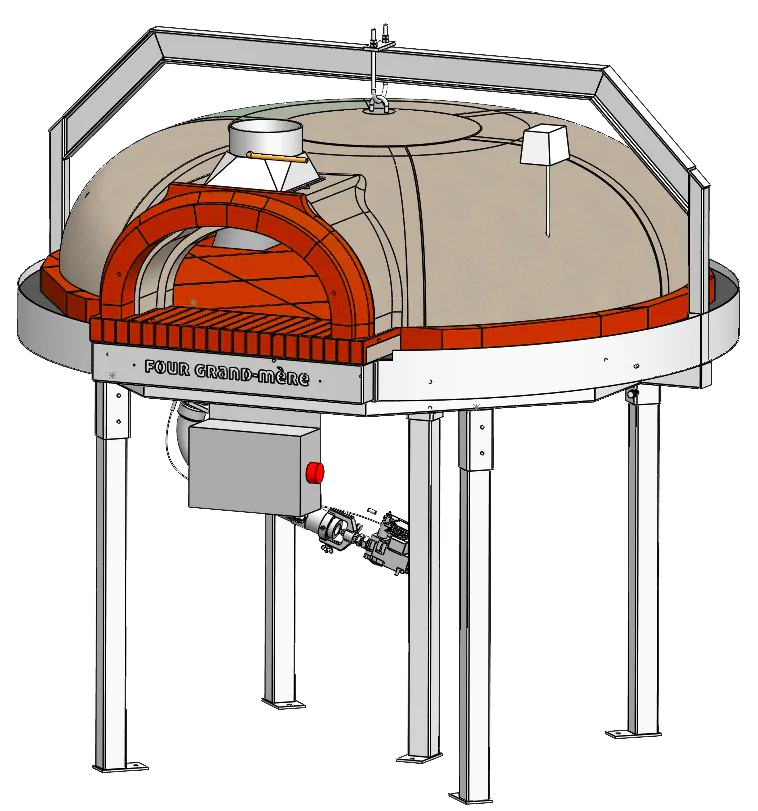

With over 40 years of experience as a French manufacturer of wood fired ovens, Four Grand-mère now offers the widest selection of professional pizza ovens on the market.

With around 40 wood or wood-gas models and numerous optional equipment, we can satisfy the specific needs of any restaurant or pizzeria, of any size.

Our wood ovens for pizzerias

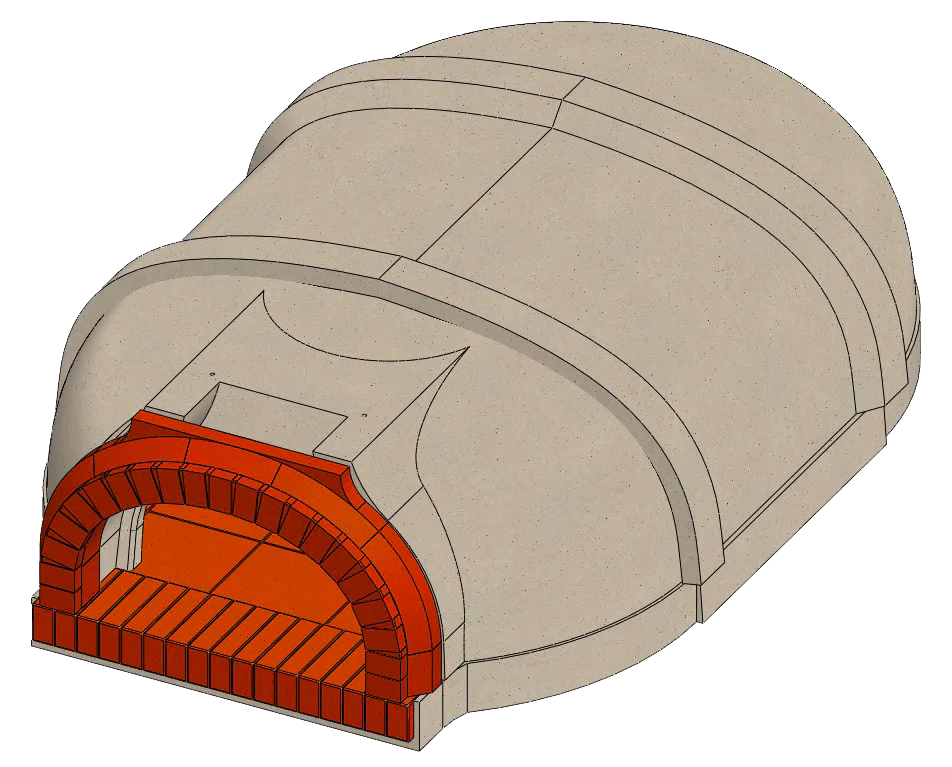

Wood-fired pizza: an incomparable show

With soft dough and crispy crust, wood-fired pizza is sure to delight gourmets of all ages, and its marketing power is formidable. Install a wood-fired oven where customers can see it: the spectacle of the flame and the traditional movements of the pizza maker will instantly charm them!

Looking to add this emblematic dish to your menu to boost your restaurant’s sales and profitability?

Four Grand-Mère offers a whole range of professional pizza ovens, made of brick or refractory chamotte, for unrivalled cooking quality.

Use them to cook pizzas or tartes flambées perfectly, to grill meat or fish, or to prepare lasagne au gratin, etc.

With fixed or rotating floor, with or without individual rotating plates, our wood ovens are designed to meet the needs of all professionals, from the small trattoria to large restaurant chains.

💡 Even with our wood and gas ovens, you can enjoy the ‘wood-fired pizza’ designation as long as you cook your pizzas using wood as the main energy source.

Our different ranges

A unique choice of professional pizza ovens

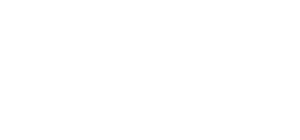

We make all our ovens 100% by hand in France, with robust French materials that have been carefully selected to last: bricks, chamotte, stainless steel fibre-reinforced refractory mixture…

Our ovens for pizzerias and restaurants are also designed in detail to save energy and consume up to 30% less wood compared to a standard oven:

- Very thick refractory floor, very well insulated with no less than 8 cm of vermiculite mortar or compressed mineral fibre.

- Lowered vault with a height of 27 to 34 cm maximum, depending on the models.

- A cast-iron outer door for an attractive, traditional look to the oven.

- For the vault, double or triple mineral fibre insulation, 3 times more effective than chamotte and 10 times more effective than sand.

- For wood ovens only, a removable insulating door helps retain heat from one service to another and saves time when reheating.

By choosing a Grand-Mère oven, you can take advantage of high-performance equipment that is made not only to optimise your energy costs, but also your working comfort.

The exemplary insulation of our ovens ensures that the heat escapes almost exclusively through the door when it is open. Therefore, the energy consumed is used to cook the food in the oven and not for the kitchen or dining room, for your own well-being and that of your customers!

Our wood ovens for pizzerias

Or a 5-year guarantee for ovens with a chamotte vault

To reveal all the flavours of your pizzas

For beautiful Neapolitan pizzas directly cooked on the floor

Or optional assembly by our fitters, in France only.

Our different ranges

A unique choice of professional pizza ovens

Whether you choose our wood or wood and gas fired-ovens, you can be sure that your dishes will be cooked in the best possible way. Many options are available to suit all configurations: specific dimensions, raised roof, double-entrance ovens, or with a ‘show’ glass door so that the magic of the flames can be enjoyed by all…

Roman wood-fired ovens

Wood fired ovens with static floor and cooking chamber from 0.49 to 3.25 m². The reference traditional solution.

See 19 models

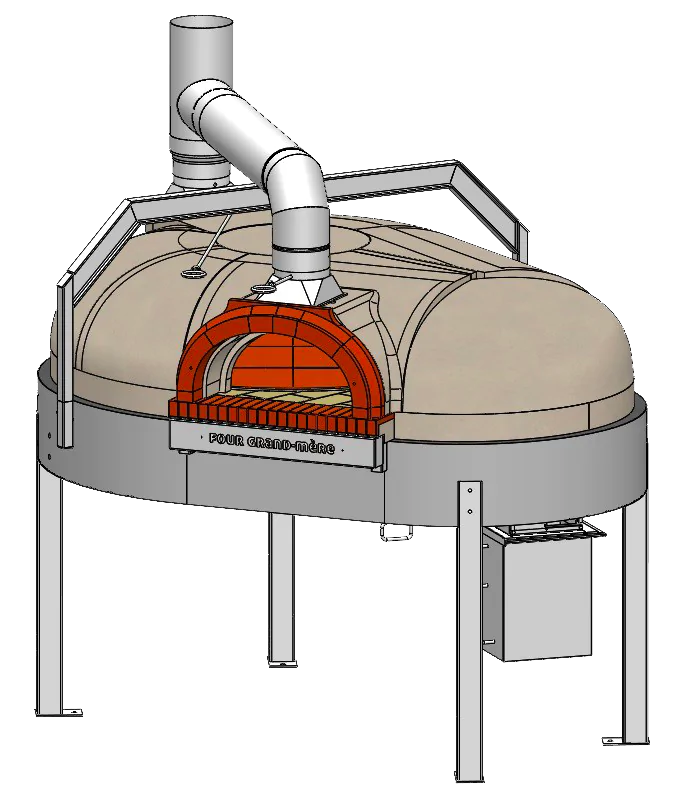

Our rotating pizza ovens

Thanks to the rapid rotation of the floor, these wood ovens reduce the workload of the pizza maker considerably and guarantee a perfect cooking.

See 6 models

Pizza ovens with turntables

A unique invention for a perfect cooking consistency and a production capacity of up to 150 pizzas per hour.

See 8 models

Combined wood-gas fired pizza ovens

For a rapid rise in temperature and programmed starts for 7 days, while maintaining the benefits of flame cooking.

See 11 models