Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

Read moreOur wood-fired ovens for bakers.

Discover our wood-fired ovens for bakeries: Roman, with throat or with rotating floor.

Wood-fired ovens for your profitability.

Our bakery ovens are designed down to the last detail to maximise the energy efficiency of wood, an energy source that is much more competitive than electricity, the price of which has soared:

- Lowered arch for up to 30% less fuel consumption.

- Extra-thick refractory base, 6 to 8 cm, to promote heat accumulation.

- Insulate the floor with 8 cm of vermiculite mortar or mineral wool for rotating ovens.

- For the vault, triple mineral fibre insulation, 10 times more effective than grog and 60 times more effective than sand.

And the results are there! After each heating, temperature loss is limited to 5 to 7°C per hour. Take advantage of the energy accumulated after each batch to bake brioches, tarts, quiches, meringues, etc.

If you wish, you can also cook delicious specialities with high added value over the flame: pizzas, focaccias, focaccias, etc.

Bread baked over a wood fire: a unique know-how

With its airy crumb and deliciously crisp crust, bread baked in a wood-fired oven has an incomparable taste that’s instantly recognisable. By opting for a wood-fired oven, a guarantee of authenticity, the baker is perpetuating this ancestral know-how, and the breads and baguettes are baked to perfection!

Four Grand-Mère, manufacturer of wood-fired ovens in France for 45 years, offers you a wide range of 23 models suitable for all bakery professionals: Roman, throat or revolving floor ovens.

High-performance and built to last, our direct-heating wood-fired ovens all benefit from the protected designation of wood-fired bread, ideal for promoting your expertise.

- EPV: Entreprise du patrimoine vivant (Living Heritage Company)

- 5-year guarantee for chamotte ovens

- 10-year guarantee for brick ovens

Our wood-fired ovens for bakers

For bread baked to perfection day after day

In the Vosges, using only French materials

A great way to set the scene and liven up your bakery

Direct cooking fumes into the shop or onto the street

Thanks to the metal frame, our ovens are 2 to 3 times lighter.

Our different ranges

The widest choice of ovens for all craft bakers.

All our wood-fired ovens guarantee consistent production of high-quality bread. They are available with a traditional or electric steam system.

Roman wood-fired oven

Ovens with static floors, without fireplaces: the archetypal bread oven of our countryside. The fire is made directly in the baking room. Four Grand-Mère quality at the best price.

See 6 models

Wood-fired ovens with throat

In a throat oven, the flame passes through the baking room. Four Grand-Mère offers you a range of throat ovens with lower or side firebox.

See 17 models

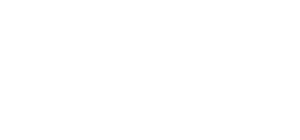

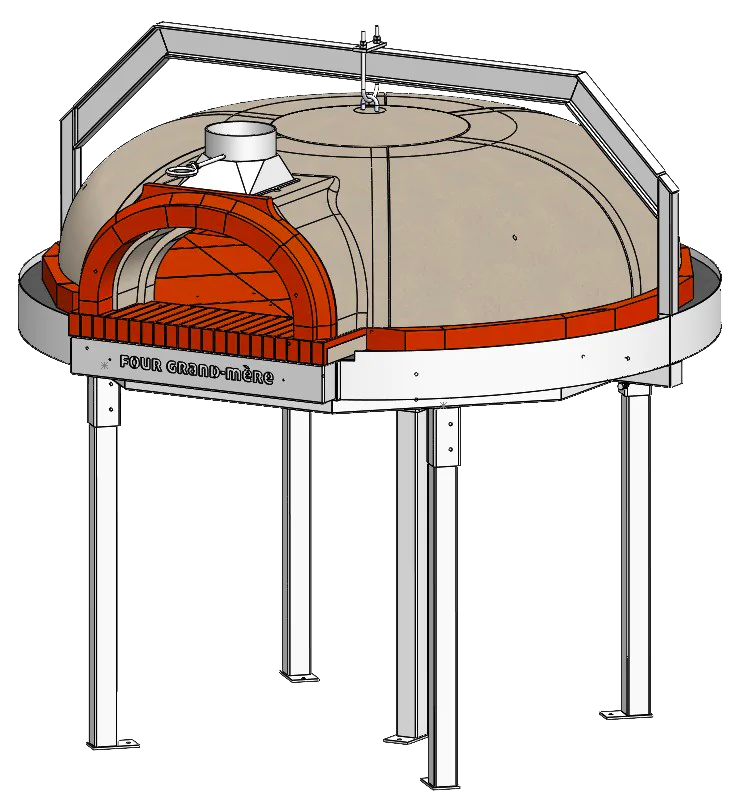

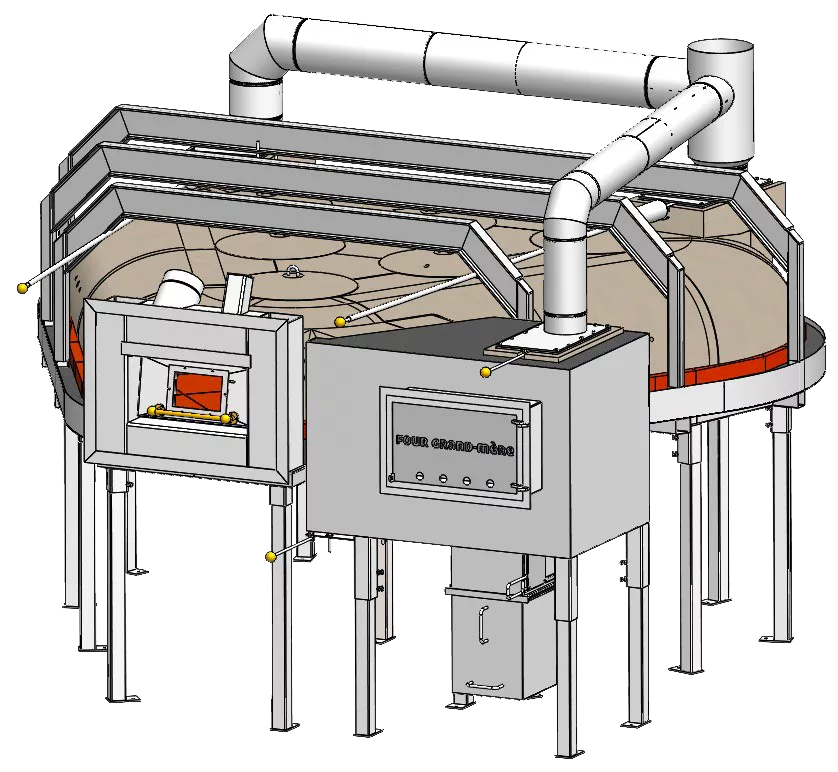

Rotating floor ovens

Side firebox with a throat oven with an electrically rotating floor. A premium oven for perfectly uniform bread baking.

See 3 modelsExamples of customer installations

FAQ

The questions most frequently asked by bakers

For most of our professional bread ovens, the first heating takes around 2 hours. And even for the 2633GI, an extremely large conveyor belt oven with a bottom surface area of 8.48 m2, the heating time does not go beyond 2 hours 30 minutes.

15 minutes is enough to bake 3 batches of baguettes for example, after a rest period of 10 to 20 minutes.

Yes, if you want, we can send 2 technicians to your site for 2 to 3 days, depending on the model selected, in France only.

Alternatively, you can install it yourself, because your oven is supplied in a kit format that is easy to assemble, with clear assembly instructions and a suitable grout for mounting the prefabricated parts. No particular masonry skills or specific tools are required. Some of our customers assemble their own ovens in just 3 or 4 days.

Imagine a life-size construction game; you really cannot go wrong!

The structure of your wood-fired oven is not fixed to the walls, and the parts are not bricked together. This means you can easily disassemble, move and reassemble your work tool.

Choosing the right wood-fired oven

Which oven should I use for my bakery?

The Roman oven

This static floor oven provides all the basic functions of a wood-fired oven, nothing more, nothing less. The fire is lit directly in the baking chamber. After the oven has reached the right temperature, the baker must remove the ashes and embers from the oven and clean the floor properly before baking the bread on the bricks.

This entry-level oven is particularly interesting for novice bakers or those with a very limited budget. However, with time, it can be quite restrictive, and repeated cleaning of the floor limits productivity.

The throat oven with lower firebox

The firebox, which is separated from the baking room, is located under the oven floor. The fire-box and baking room are linked by an opening topped by a heavy removable cast-iron part known as the ‘throat’.

The lower fire-place baker’s oven is the best choice if you need to work in a small area. Since the fire-place is located directly under the oven, it does not take up much space.

The lower firebox is also advisable if you plan to use a large oven with conveyor belt baking, as it distributes the heat very well.

The throat oven with side firebox

The firebox is next to the baking chamber, at the same height. It can be placed either on the left or right, to match the configuration of the room. With its more modern design, the side fireplace system has a number of advantages.

It is more comfortable for professionals, who no longer feel the heat in their legs when putting in or removing the food from the oven. This is also much more practical. Thanks to a flap system that can be activated by a

handle outside the oven, you can easily open or close the opening between the fireplace and the baking room. This means you avoid handling a heavy, hot cast- iron throat. Finally, supplying the floor is easier at human height.

The rotating floor

As opposed to static floor ovens, that require time to learn how to manage the temperature variations between the different zones of the oven, rotating floor woodfiredovens ensure a perfectly uniform baking experience.

By making the floor rotate during heating, you obtain uniform heating of the entire bottom. Then, during the baking, the rotation of the floor gives an incomparably regular baking.

Powered by an electric motor, the oven can be rotated forwards or backwards to quickly position the desired part of the floor in front of the door. To facilitate continuous charging and discharging, the rotation is also controlled with high precision in real time.